Turning Tooling Challenges into Proven Solutions.

Expert support in DFM, material selection, tool design, processing, and ISO 9001 guidance.

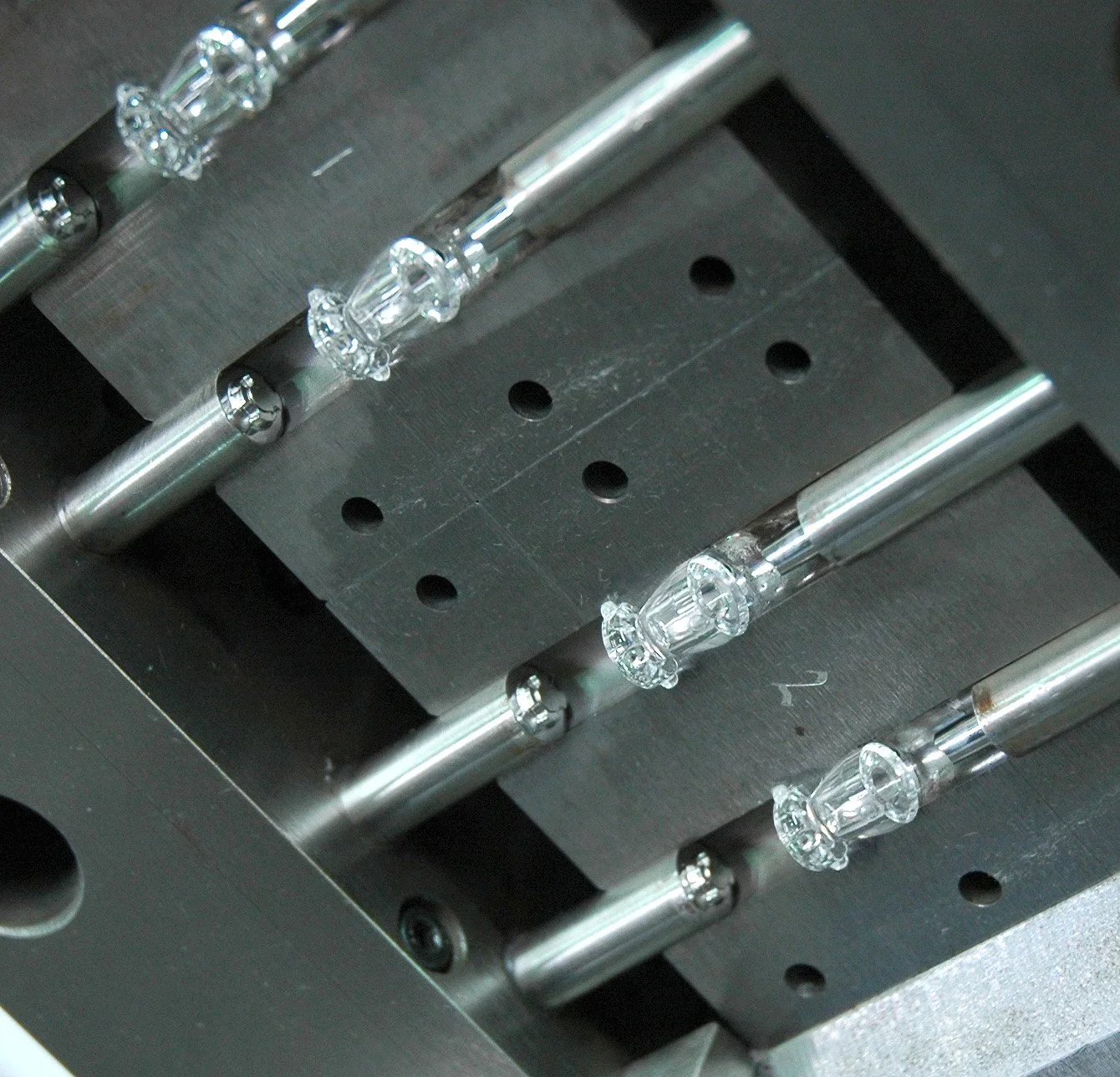

With over 30 years of hands-on experience in toolmaking and injection moulding, David Steel Consult helps manufacturers bring designs to life with precision, efficiency, and confidence.

From early-stage design for manufacture (DFM) to ISO 9001 implementation, I provide calm, practical, and technically grounded support — remotely or on-site.

Meet David Steel

I started in toolmaking at 16, driven by a simple curiosity — why things break and how to make them better.

Over three decades later, that mindset still drives everything I do. After a full apprenticeship and years on the bench, I became a senior toolmaker, then moved into CAD/CAM and aerospace precision work before running my own toolmaking and injection moulding company.

I’ve worked across industries, from automotive to medical, specialising in problem-solving, DFM improvements, and precision moulding projects.

My consultancy allows me to share that experience, helping businesses make confident, informed decisions at every stage of tooling and production.

I believe every problem has a logical solution. Sometimes, it just takes a fresh perspective and a practical plan.

Our Services

Supporting tool rooms, engineers, and moulding departments from concept to qualification.

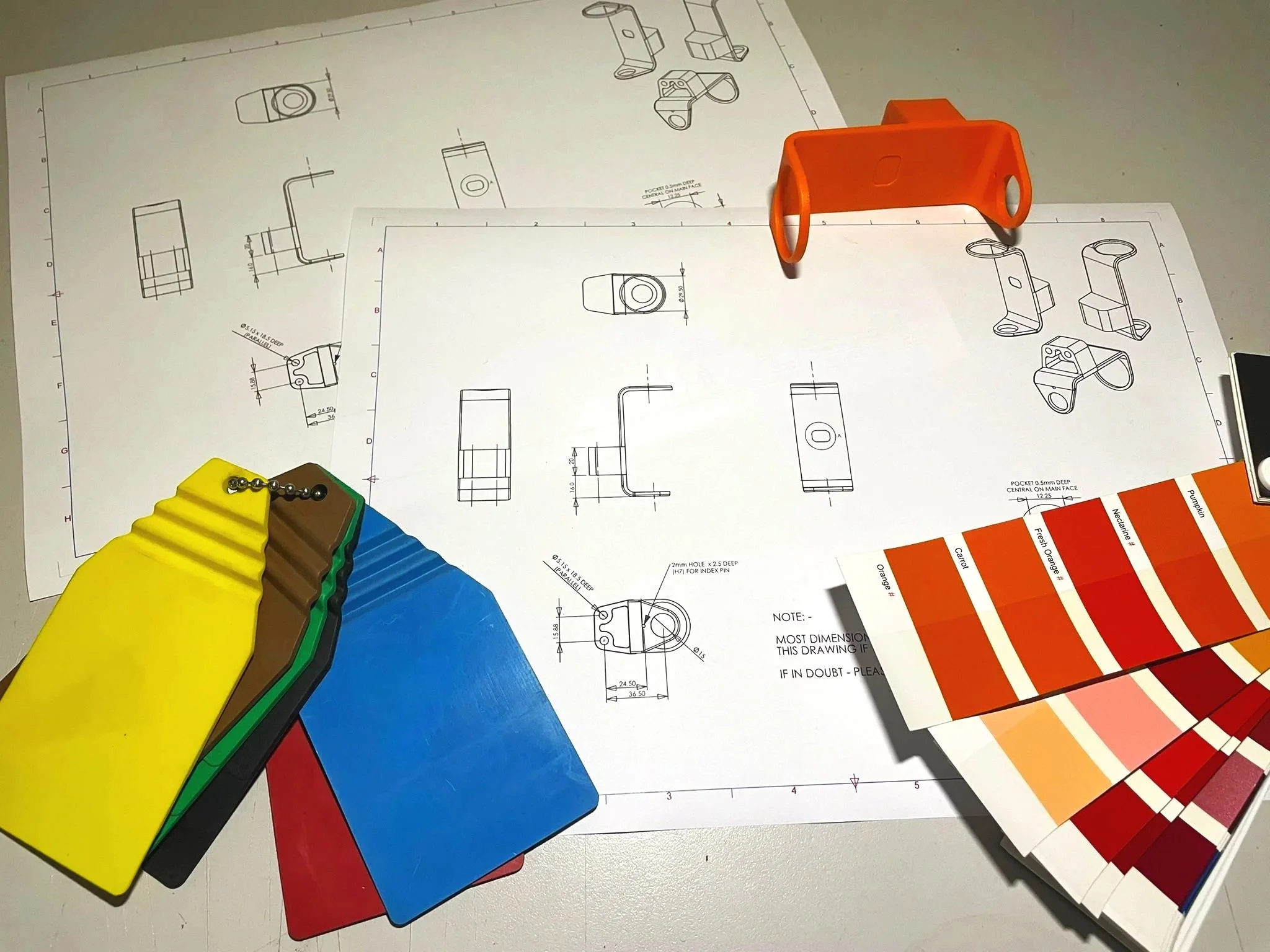

Optimising product designs for efficient and reliable tooling.

Early-stage feasibility and manufacturability reviews

Wall thickness, draft angle, and parting line advice

Design recommendations to minimise cost and cycle time

Design for Manufacture (DFM)

Processing Tips & Moulding Support

Improving part quality and consistency through process optimisation.

Process setup and validation guidance

Troubleshooting short shots, flash, and warpage

Practical solutions to improve cycle time and stability

Helping you choose the right materials for performance, durability, and processing efficiency.

Plastic and elastomer recommendations

Material comparison and testing advice

Support for regulatory or specialist applications (medical, automotive, etc.)

Material Selection

ISO 9001 Application & Guidance

Applying ISO 9001:2015 principles in real-world environments.

Implementing and maintaining quality management systems

Corrective action planning and documentation

Supplier or process audits

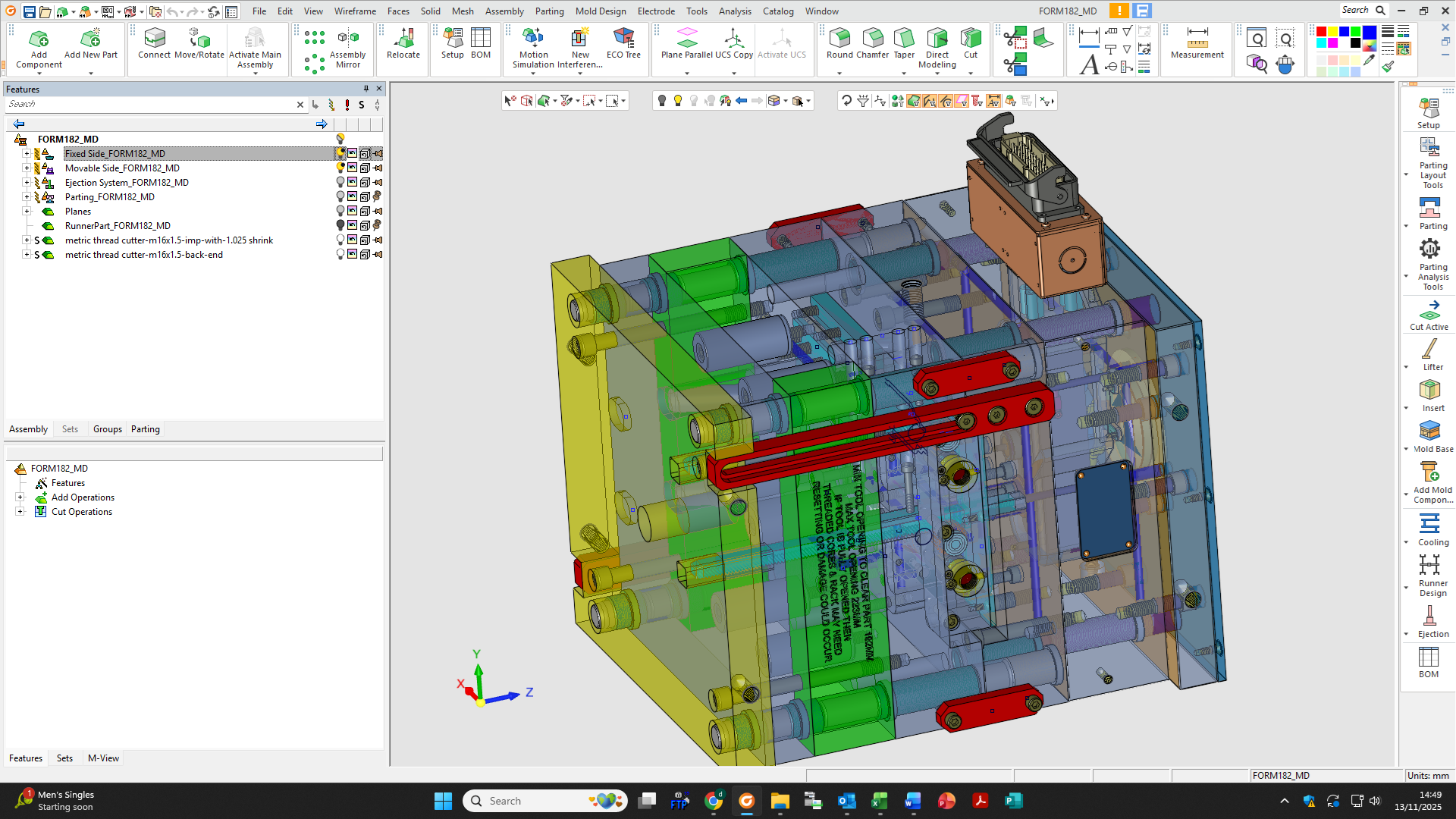

Tool Layout & Tool Design Approval

Independent review and approval before manufacture.

Tool concept validation

Gate, runner, and cooling layout checks

Design sign-off from a toolmaker’s perspective

Communication between OEM and supplier

Book a consultation or request support today.

Fill out the contact form below and we will be in touch to book a discovery call.

Get in touch

For project reviews, tooling advice, or processing support, please fill in the contact form and we will get in touch within 48 hours.